관련링크

본문

VJ-T (M8 & M10 & M12)

VJ-T (Screw-in) for onshore

- New fastening system of self tapping screw type

- No need fastener gun / powder (cartridge)

- Easily, Quickly, Simply, Confidently

- Pull-out load : 14.0kN (avg.) / Shear load : 13.0kN (avg.)

VJ-T Fixture Pin

A new technology of Grating & Multi-purpose Fastening System

Principle of VJ-T Fixture Pin

-

- The VJ-T Fixture pin can be used as an alternative to the welds and bolts used to attach materials to structual steel and for fastening applications in onshore / shipbuilding and offshore plants.

- The VJ-T Fixture pin series were made of forged and integral, Taptite (Self-screw type).

- Taptite thread will be screwed in into a pre-drilled hole. and taptite screw is tapping its own internal mating threads when installed into base material.

Advantages of VJ-T Fastening System

For base material th'k ≥ 6.0mm, the fastener is intended to be set in a pre-drilled pilot hole.

The advantages of pilot hole is no through penetration of the base material therefore no rework of the protective surface coating on the back side is needed.

-

- No maintenance – No corrosion – No inspection – No painting damage

- Work Efficiency – Easy / quick installation ( Only 15 seconds for VJ-T fastener installation )

- High safe – No drop hazard – longer durability

- Easy removal / reinstall for maintenance

Application for Grating Fastening

VJ-T [M8]

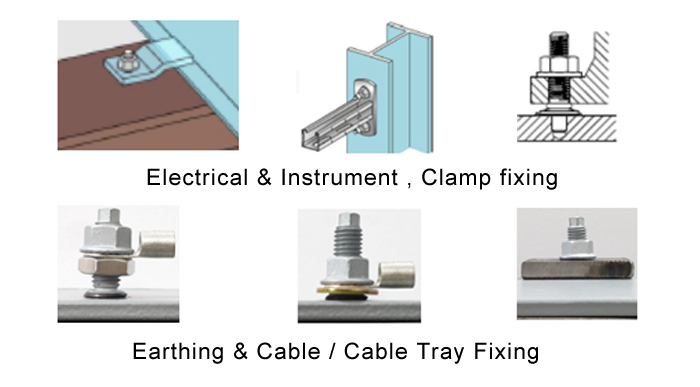

Application for Multi-purpose Fastening

VJ-T [M10] / VJ-T [M12]

Structure of VJ-T Fixture Pin

- Material : Carbon steel + GEOMET 720 Coat. or PFZnNi Coat.

- Feature

- Forged Integral type [KIST Patent]

- High pull-out / shear load through taptite screw (triangle thread)

- Salt spray test ≥ 1,000 hr - No visible red rust

- Strong durability of corrosion

OUR OFFICE

OUR OFFICE